On September 25, 2023, the National Health Commission released 85 national food safety standards and 3 amendment notices (NHC Announcement No. 6 of 2023), including 17 standards related to food contact materials, comprising 5 product standards (plastics, metals, rubber, composite materials, inks) and 12 method standards (migration general principles, method validation general principles, specific migration quantity test methods, etc.)."

This article will introduce GB 4806.14-2023 National Food Safety Standard for Inks Used in Food Contact Materials and Articles (hereinafter referred to as the "Ink Standard"). The official implementation date of this standard is September 6, 2024.

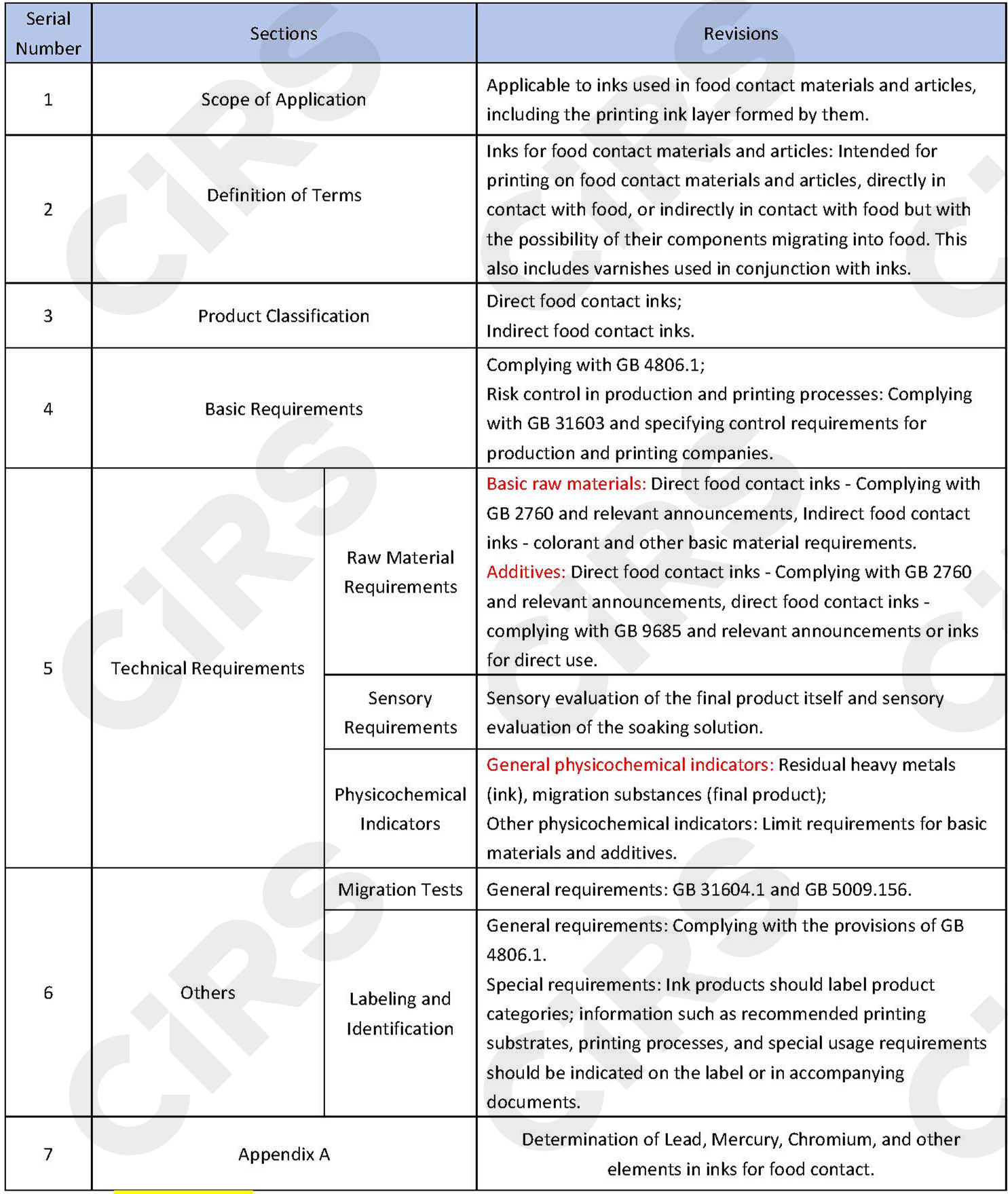

This marks the first release of a food contact materials and articles ink standard in China, providing regulatory and technical support for the production and compliant use of inks intended for food contact materials and articles. The main contents are as follows:

Table 1: Main Contents of GB 4806.14-2023

Key Points of Concern

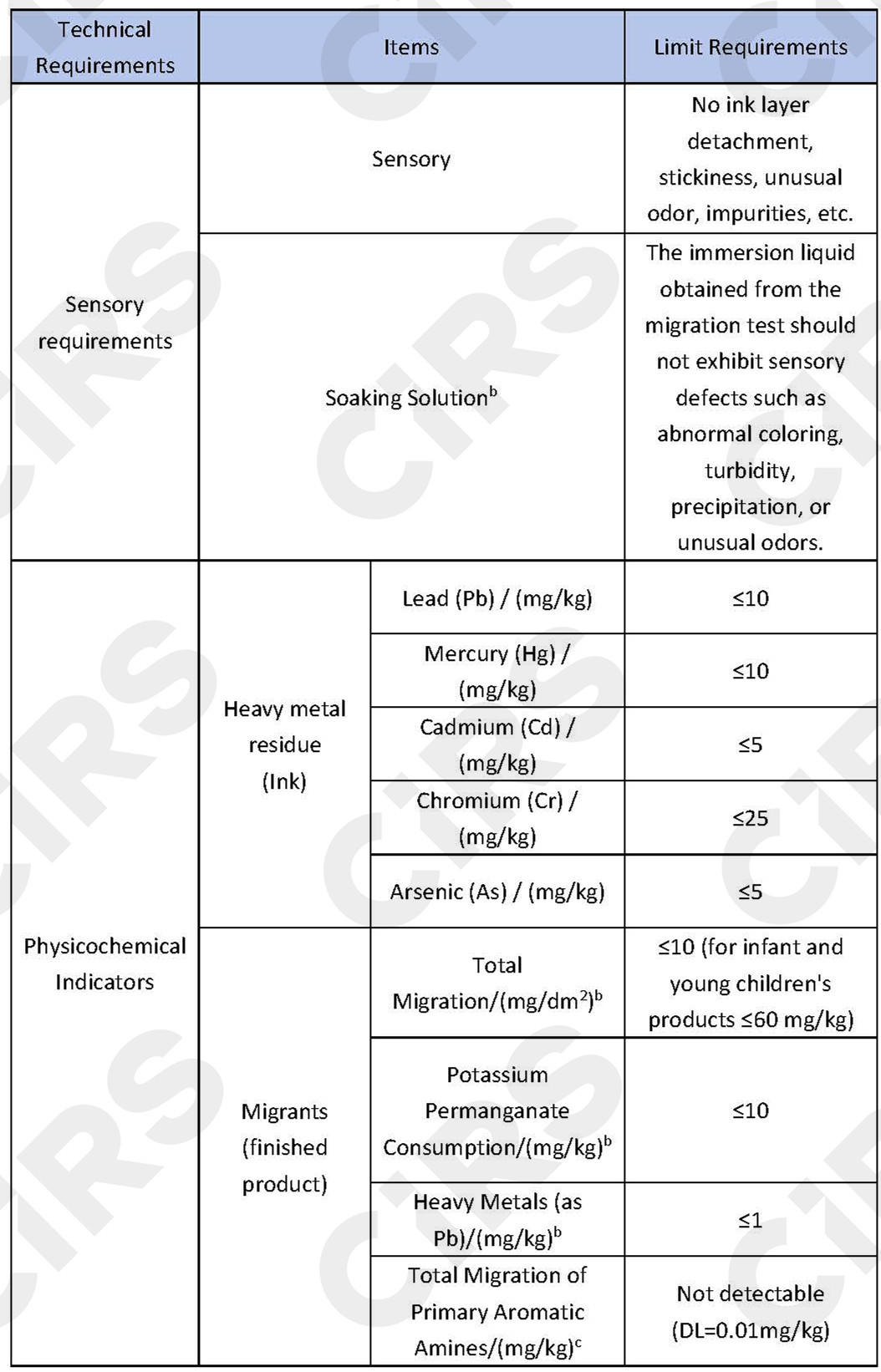

As indicated above, the ink standard framework is essentially consistent with other product standards, with technical content encompassing three aspects: raw materials, sensory, and physicochemical index requirements. The main technical specifications are shown in Table 2.

Table 2 GB 4806.14 Standard Technical Requirementsa

a The items listed in the table do not cover specific migration limits and other physicochemical indicators.

b Applicable only to ink layers for direct food contact.

c Applicable only to printing ink layers containing aromatic isocyanatocool and azo colorants, etc., which may produce primary aromatic amines.

Warm Reminder

Ink, as a special category of food contact material and product, can be influenced by different processing methods and final product applications, which impact its safety and hygiene. Therefore, it is necessary to exercise control over critical aspects. Regarding ink standards, CIRS C&K Testing advises all relevant parties, including businesses, industries, and technical organizations, to proactively pay attention and offers the following recommendations:

A: Focus on product categorization and varying safety requirements

In practical application, it is important to consider that printing inks on the surface of some food contact materials come into direct contact with food, posing a higher migration risk. Therefore, this standard categorizes them into "inks for direct food contact" and "inks for indirect food contact," and based on the differences in risk, establishes distinct control requirements, especially for raw materials and migration index requirements. Clearly defining the category of ink products is key to risk management.

B Strengthen compliance management of raw materials

The standard specifies allowable raw material requirements based on product categories. For "inks for indirect food contact," colorants that are based on lead, mercury, cadmium, hexavalent chromium, arsenic, antimony, selenium elements, or their compounds are not allowed, and their purity must comply with the requirements of GB 9685. Other basic raw materials should be approved for use in food contact materials and products. As for "inks for direct food contact," higher requirements are set for basic raw materials and additives, all of which must comply with GB 2760 and relevant announcements, with quality specifications meeting the corresponding requirements. Differences in usage scenarios will lead to changes in compliance requirements, so it is advisable for the industry to pay special attention.

C Enhance control over production and printing processes

The production and printing processes of ink products can impact the safety of the final product. The standard clearly outlines the responsibilities of production companies and printing companies. Production companies must focus on controlling raw material selection, process control, and product information transfer, among other aspects. Printing companies must control their risks through packaging design, the printing process, and aim to minimize ink usage while achieving the desired printing effect.

CIRS C&K Testing has acquired the full set of technical testing capabilities for the new standard mentioned above. If you have any needs, please get in touch with us via test@cirs-group.com.